Dr. Benoit Merle is a group leader and faculty member with the University of Erlangen-Nuremberg in the Department of Materials Science and Engineering. He is a lecturer, mentor to graduate students and manages the nanomechanical research lab.

We interviewed Dr. Merle about his recent publication, which investigated focused ion beam (FIB) milling and fracture toughness characterization of gold thin films.

Tell us about the research goals of your lab

Thin films and nanostructured materials are present in a growing number of daily-life appliances, tools and vehicles. While they provide massive gains in terms of performance and efficiency, they are also critical components that absolutely should not fail, lest a whole device would cease to function. Unfortunately, it is neither easy to measure nor to forecast their mechanical properties.

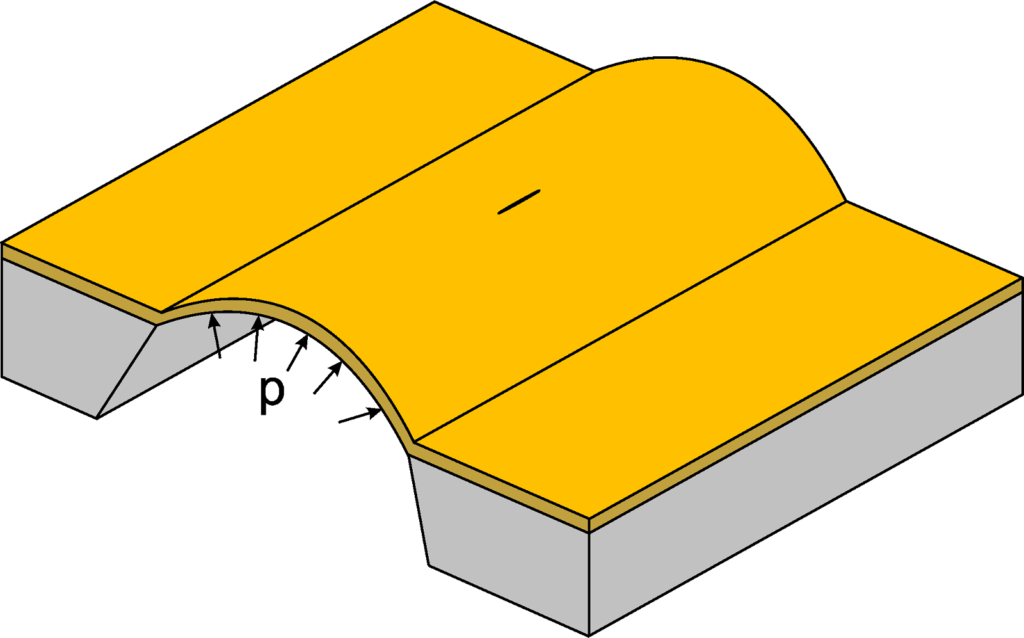

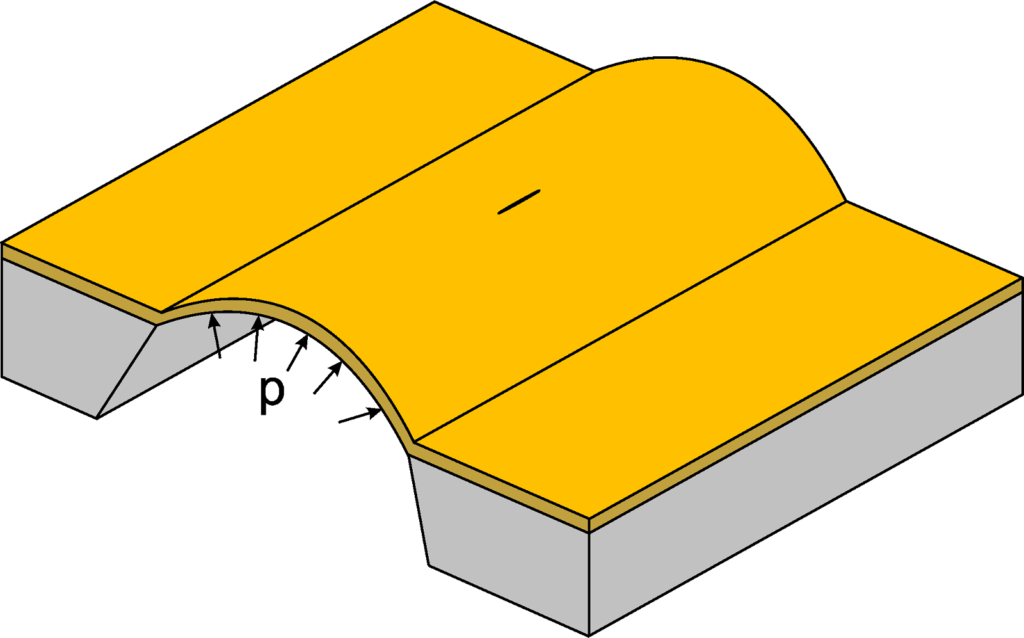

Schematics of bulge testing with a notched gold thin film. The membrane is mechanically loaded with gaseous nitrogen. This technique is used to measure the fracture toughness of thin films.

My research focus is on gaining a fundamental understanding of the small-scale deformation of the materials (in the nanometer to micrometer range), so as to predict how thin films and nanostructured materials will deform and fail. Generous financial support from the European Research Council (ERC) for the next five years will allow me to expand my research to shock and impact conditions, which are critical for the lifetime of many coatings.

What new findings do you present in your recent publication?

In our previous publications, we had uncovered the reasons why metallic thin films become increasingly brittle as their thickness is reduced. Reaching these conclusions was made possible by a nanomechanical technique requiring preliminary structuring the thin films samples with a focused ion beam (FIB). The latter process inevitably introduces some ion damage to the specimens, which was feared could introduce a bias in the measurements.

Our goal with this publication was to prove that the ion damage is too small to affect our nanoscale fracture toughness measurements. This serves not only our own past research, but also enables measuring materials parameters that would otherwise be inaccessible at this small scale. Structuring samples by FIB milling has gained strong traction in the nanomechanical community.

What type of focused ion beam (FIB) milling did you test?

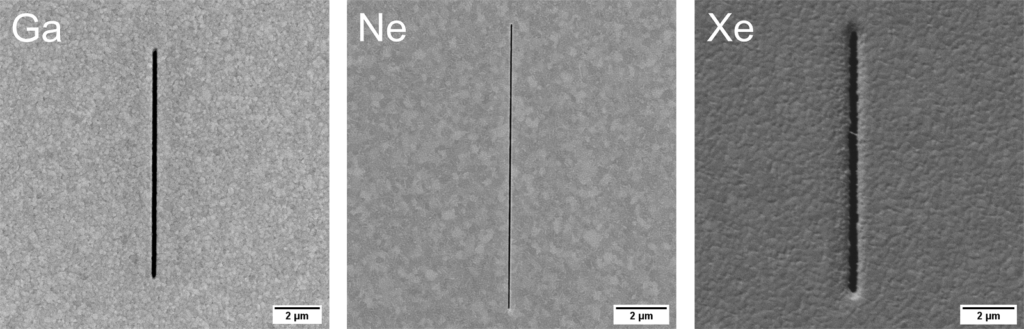

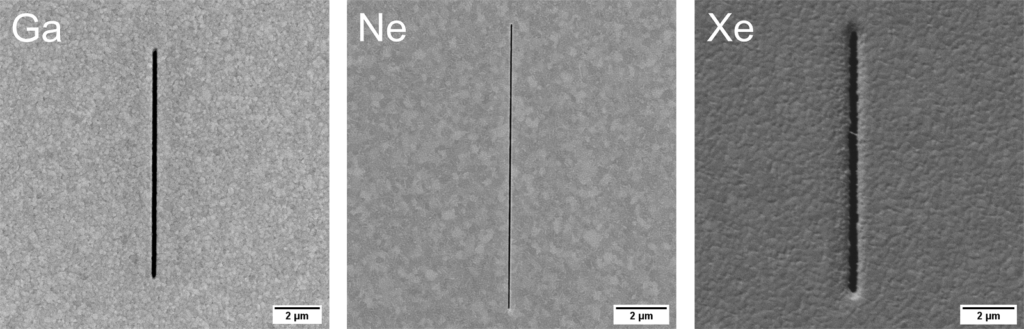

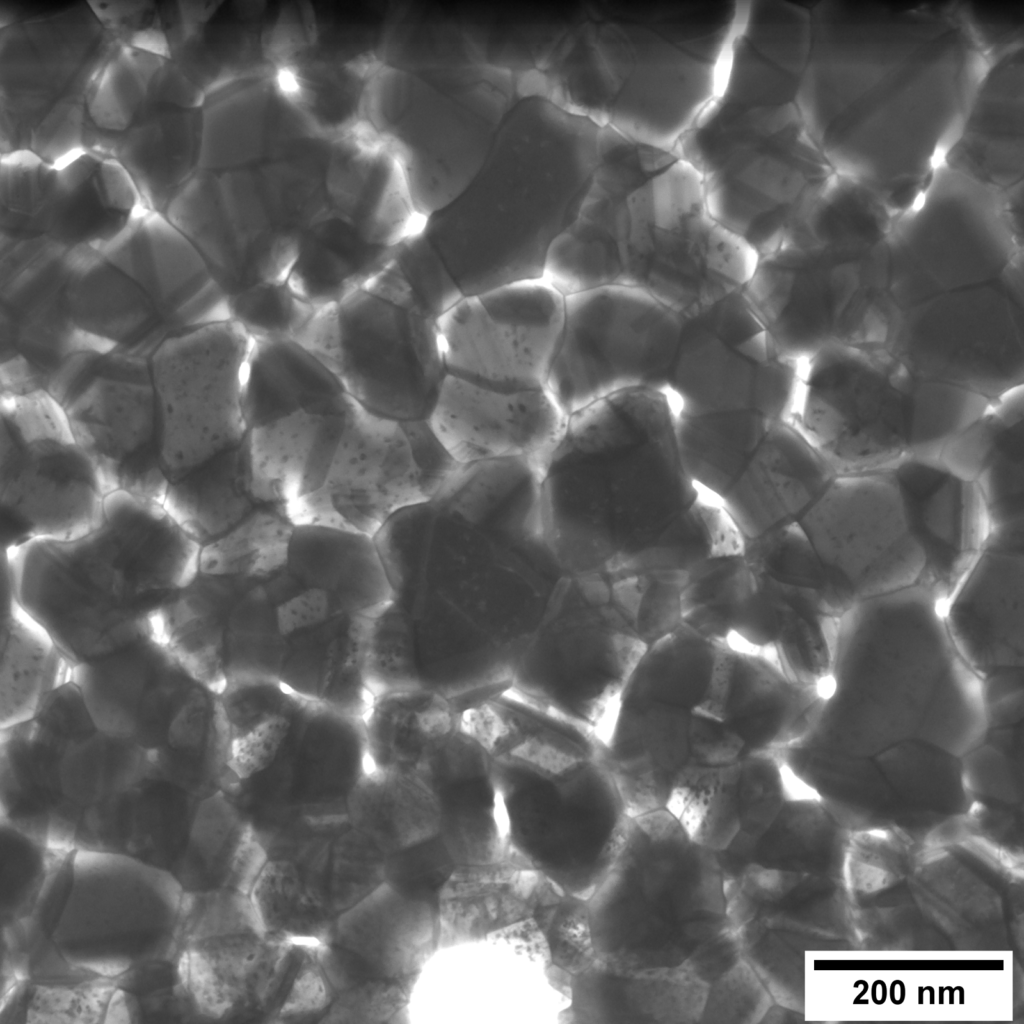

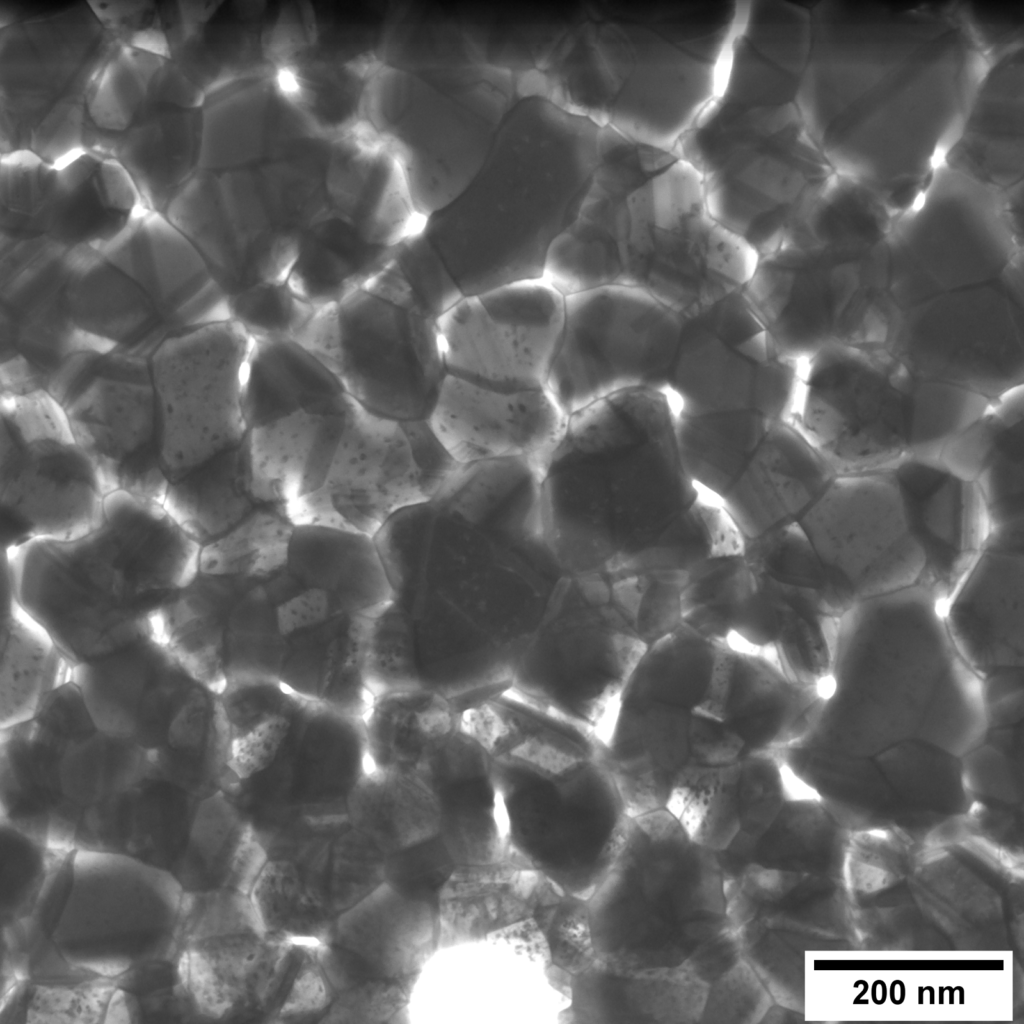

In cooperation with Dr. Jeff Wheeler at ETH Zurich and with the Max-Planck Institute for the Science of Light, we processed identical samples with different FIB microscopes, which were based on different ion technologies: gallium, neon and xenon. Our Monte Carlo simulations and the literature predicted that the much different sizes of these ion species would result in much different damage to the specimens. This was confirmed by directly imaging the surrounding area of the structures by scanning electron microscopy (SEM) and transmission electron microscopy (TEM) after FIB processing.

Nonetheless, varying the ion species did not noticeably affect our fracture toughness measurements on the gold thin films. We rationalized that the ion damage is so local and small compared to the size of the FIB-milled features that its effects are fortunately negligible and valid fracture toughness measurements can be carried out by nanomechanical testing.

Local FIB damage around a notch in a gold film evidenced by scanning transmission electron microscopy (STEM).

Read the full article: Applicability of focused ion beam (FIB) milling with gallium, neon, and xenon to the fracture toughness characterization of gold thin films. Link

Learn about ZEISS solutions for focused ion beam (FIB) microscopy.

Read Next