Researchers use advanced imaging methods to understand the structure-property relationship

Dr. Roland Brunner is a Group Leader for Material and Damage Analytics in the Microelectronics Division at the Materials Center Leoben (MCL) in Austria. The group strongly focuses on 3D nano/micro-structure image- based characterization and analysis with respect to innovative materials used in microelectronics and energy, to trigger improved functional material design for industrial applications.

We spoke with Dr. Brunner about his research and recent publication: “Multi-scale quantification and modeling of aged nanostructured silicon-based composite anodes.”

In this paper, the development of the image analysis workflow and analysis of the 3D image data obtained from FIB-SEM and synchrotron tomography was contributed by first author Thomas Vorauer (PhD student) and co-author Dr. Fereshteh Falah Chamasemani (Postdoc).

What are your research goals?

My group applies advanced imaging methods (e.g. microscopy, synchrotron-, neutron- and x-ray based) and develops image processing algorithms for materials science relevant topics. In particular, we focus on materials for microelectronics and energy related materials.

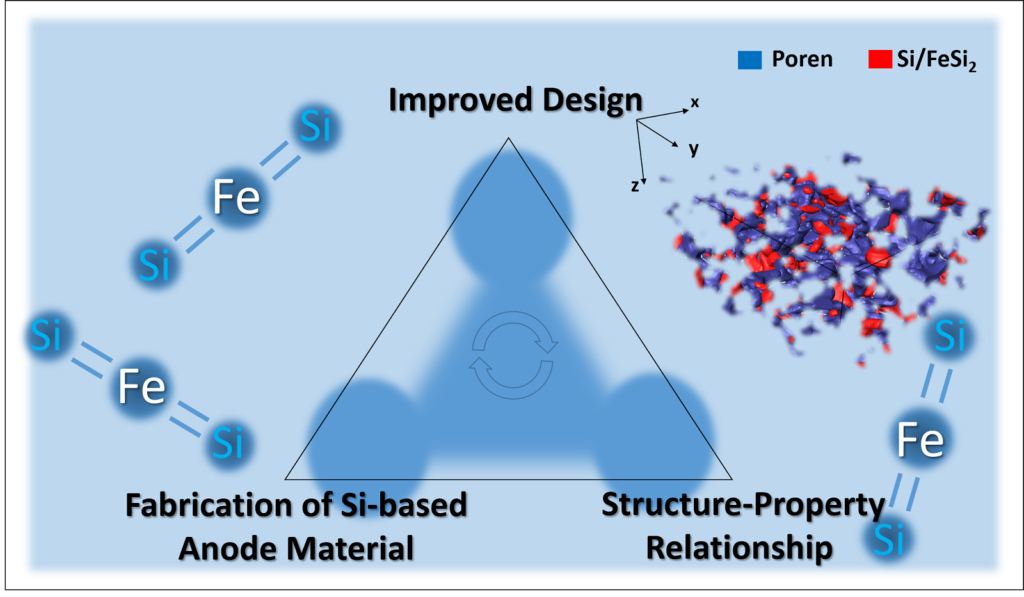

Our research goals are to gain a deep understanding of the structure-property relationship on all relevant length scales. This will yield design guidelines to improve the materials beyond the state of the art.

One of our big research questions concerns the improved design of anode materials, which provide less aging and long cycle stability. Recently we published novel findings with respect to the inhomogeneous lithiation of the active material within nanostructured silicon-based anode materials, induced by the morphology changes due to cycling.

Tell us more about your recent publication:

Si-based Li-ion batteries are among the most promising candidates for decentralized storage systems in the area of renewable energy, e-mobility, or mobile electronic devices.

However, one challenge with Si is its volumetric expansion upon lithiation (up to 300%). This can result in fracture, peeling off or delamination in the microstructure of the anode material and lead to lower lifetime expectancy. Irreversible capacity loss can also occur due to continuous solid electrolyte interface (SEI) formation which limits the migration of the Li-ions between the electrolyte solvent and the active material. Dual phase alloy systems, like Si/FeSi2 nano composites, have great potential as stable anode materials in Li-ion batteries to counter these effects. However, their characterization at different scales and throughout their aging remains challenging due their complex architecture.

Our goal was to gain a deep understanding of the structure-property relationship and aging on all relevant length scales. This is critical to yield design guidelines to revolutionize the different cell component materials.

What were your key findings in the publication?

We worked in a multidisciplinary team and used a multi-scale characterization approach as well as modeling to collect quantified structural information at all relevant length scales. This provided insight on the evolution of the Si/FeSi2 compound particles during cycling and their effect on Li-ion diffusion within the proximate pore network.

The experiments were performed on industrial relevant samples fabricated by VARTA Micro Innovation GmbH. CEA (French Alternative Energies and Atomic Energy Commission) performed and analyzed scattering experiments to understand the (de-) lithiation and volumetric irreversible structural changes of the Si/FeSi2 nanoscale phase. These were combined with nano-FIB-SEM tomography (also performed by CEA) and synchrotron tomography, (performed at ESRF – The European Synchrotron Radiation Facility – by my team with support from L. Helfen). Lastly, modeling of the local concentration of Li-ion in the anode material was performed at the University of Warwick using the collected morphology data as an input.

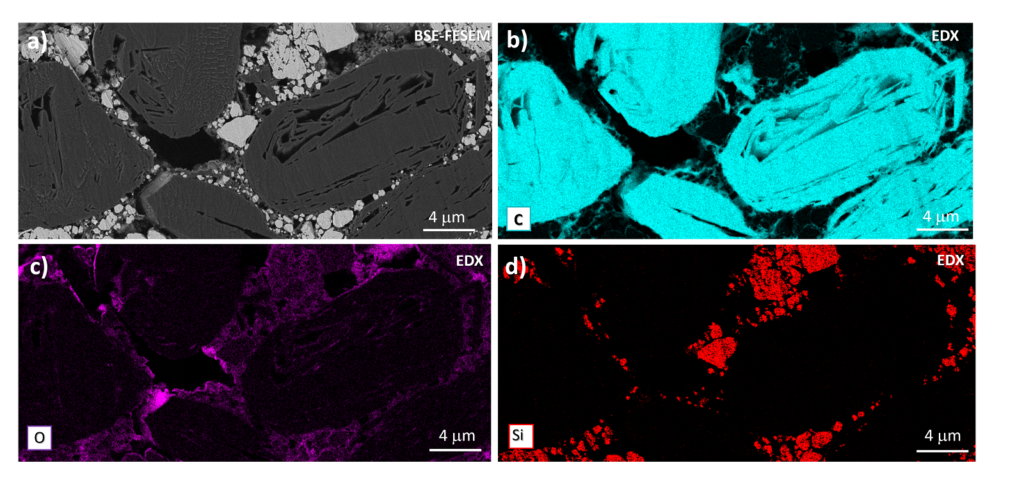

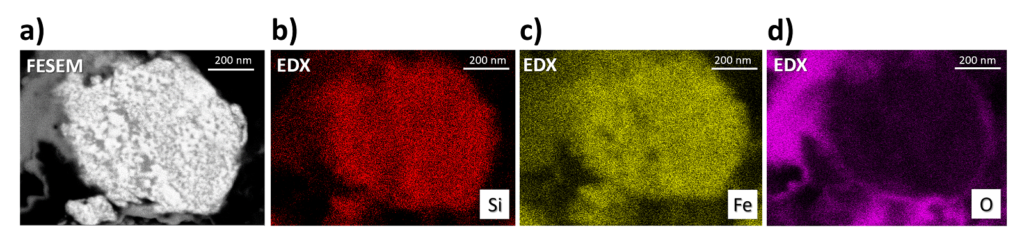

Image analysis and quantification of the morphology and its changes due to cycling was a key element in the research. Using the tomography data from the nano-FIB-SEM and the synchrotron was critical for the quantification of the morphology, but also very difficult due to the complex multi-phase structure and measurement artifacts. Two members of my team, T. Vorauer (PhD student) and F.F. Chamasemani (postdoc) were instrumental in developing an appropriate image analysis workflow to accurately quantify the obtained FIB- and synchrotron-tomography image data. This allowed us to gain the necessary structural information.

Further, we used a ZEISS GeminiSEM field emission scanning electron microscope (FE-SEM) equipped with the Ultim Extreme energy-dispersive X-ray (EDX) system from Oxford Instruments and operated with window-less configuration to correlate chemical information (elemental mapping on nm scales) with the morphology. The elemental mapping gave us an understanding of the spatial distribution of the chemical elements in the anode material. This information was crucial to understand the architecture of the microstructure in more detail. In particular, I would like to acknowledge technical support from B. Sartory and J. Wosik, both at MCL, for the FESEM-EDX measurements.

Where do you see your research going next?

The previous work was funded by an EU H2020 Project called Sintbat (Proj. No. 685716). We continue our work on Si-based anode systems within the follow up EU-project ECO2LIB (Proj. No. 875514).

Based on the gained knowledge in our previous work, we will try to enhance the mechanical stability of silicon-based anodes by investigating more advanced structural designs on micro/nm-scale to improve the cycle life even more. The complexity of the structure will definitely increase; however, it should be still interesting in terms of an ecological and economical production. Due the complexity of the materials under investigation, more sophisticated image analysis workflows will be necessary for the quantification of the anode morphology and its changes. Therefore, we are working on the implementation of machine learning based algorithm within our image analysis workflows.

With respect to the microscopy, our next steps comprise the use of ever higher resolution 3D imaging techniques to study the damage mechanism for different states of charge in more detail. Feedback will be provided to the production to possibly adapt the architecture of the next generation anode material for further improvement.

Learn More

Read the article “Multi-scale quantification and modeling of aged nanostructured silicon-based composite anodes“

Learn about the ZEISS technology mentioned in this article, including FIB-SEM nanotomography and FE-SEM solutions.

Read Next

The post Improving the Design of Anode Materials in Lithium Ion Batteries appeared first on Microscopy.